This guide provides essential information for operating and maintaining Ski-Doo snowmobiles‚ ensuring safety‚ performance‚ and longevity. Follow these instructions carefully to maximize your riding experience.

Welcome to the Ski-Doo instructions guide‚ designed to help you safely operate and maintain your snowmobile. This manual covers essential information for optimal performance and longevity.

1.1 Brief History of Ski Doo and Its Importance

Ski-Doo‚ developed by Bombardier in 1959‚ revolutionized winter transportation with its invention of the snowmobile. Joseph-Armand Bombardier’s innovative design transformed winter mobility‚ creating a new recreational market. The first Ski-Doo models were simple‚ lightweight‚ and affordable‚ making snowmobiling accessible to the masses. Over the years‚ Ski-Doo has led advancements in technology‚ such as the REV platform in 2003‚ enhancing performance and rider comfort. Today‚ Ski-Doo remains a leader in the snowmobile industry‚ offering a wide range of models for recreation‚ racing‚ and utility purposes. Its impact on winter sports and exploration is unparalleled‚ making it a cultural icon.

1.2 Why Following Instructions is Crucial

Adhering to Ski-Doo instructions is essential for ensuring safety‚ optimal performance‚ and longevity of your snowmobile. Proper operation and maintenance‚ as outlined in the manual‚ prevent accidents and mechanical failures. Following guidelines helps riders understand controls‚ perform pre-ride checks‚ and troubleshoot issues effectively. Neglecting instructions can lead to unsafe conditions‚ reduced efficiency‚ and costly repairs. By following the recommended procedures‚ riders can maximize their snowmobiling experience while maintaining the vehicle’s reliability and durability. Safety handbooks and manuals are provided to empower users with knowledge‚ making adherence to instructions a critical aspect of responsible ownership and operation;

Model-Specific Instructions

Model-specific instructions are tailored to the unique features and requirements of each Ski-Doo snowmobile. Understanding your model’s design‚ whether it’s a REV Series or Summit 800‚ ensures proper operation. The manual provides detailed guidance for maintenance‚ troubleshooting‚ and customization. Model year designations‚ such as 2017 Ski-Doo MX Z X 850 E-TEC‚ highlight specific updates and innovations. The shop manual is a critical resource‚ offering precise instructions for repairs and adjustments. Familiarizing yourself with these resources ensures optimal performance‚ safety‚ and longevity of your snowmobile. Always refer to the appropriate manual for your model year and type to maintain reliability and efficiency.

Each Ski-Doo model has unique features‚ such as the REV Series or Summit 800‚ requiring specific maintenance and operation. The shop manual provides detailed guidance for repairs and adjustments.

2.1 Popular Ski Doo Models and Their Unique Features

The Ski-Doo MX Z X 850 E-TEC is renowned for its innovative chassis and powerful engine‚ offering exceptional agility and performance. The REV Series‚ including the Summit 800‚ features a lightweight design and advanced suspension‚ ideal for deep snow adventures. The Tundra II stands out for its versatility‚ combining utility and touring capabilities. Each model is engineered with unique technologies‚ such as the E-TEC engine or the LinQ attachment system‚ enhancing both performance and customization options. These models cater to diverse rider preferences‚ from speed enthusiasts to backcountry explorers‚ ensuring unparalleled riding experiences.

2.2 Understanding Model Year Designations

Ski-Doo models are designated by specific codes‚ with the first two digits indicating the model year (e.g.‚ “17” for 2017). Letters and numbers denote series and engine size‚ such as “MX Z X 850 E-TEC.” This system helps identify features‚ updates‚ and compatibility. For instance‚ the “REV Series” indicates a lightweight chassis‚ while “E-TEC” signifies a direct-injection engine. Knowing the model year and designation is crucial for maintenance‚ repairs‚ and accessing the correct shop manual. This coding ensures owners can easily identify their sled’s specifications and requirements‚ aiding in proper care and customization.

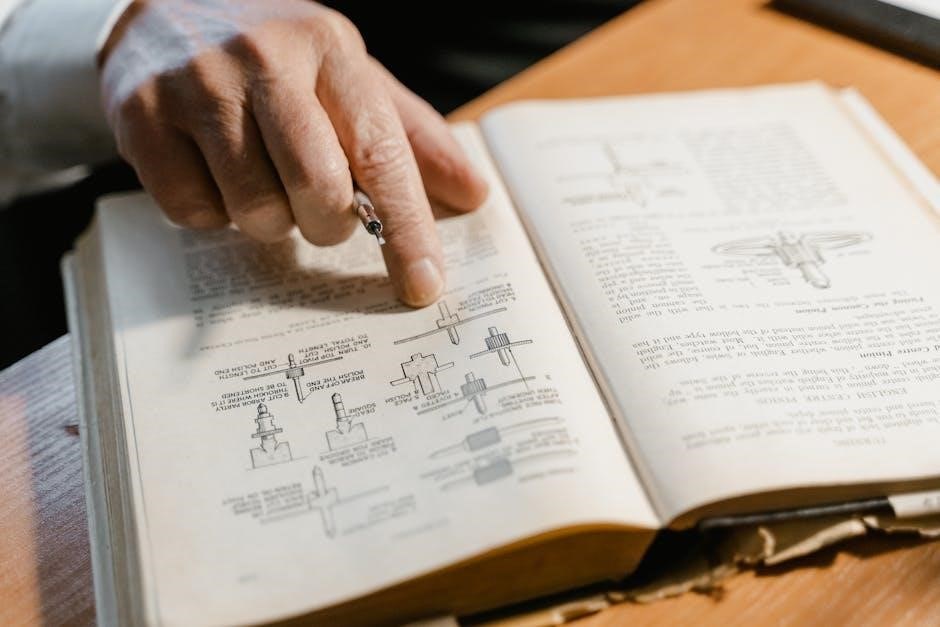

2.3 The Role of the Shop Manual

The shop manual is an indispensable resource for Ski-Doo owners and technicians. It contains detailed specifications‚ repair procedures‚ and maintenance schedules tailored to each model year and series. From engine tuning to suspension adjustments‚ the manual provides step-by-step guidance. Diagrams and exploded views help visualize complex components. Regularly updated‚ it ensures compliance with the latest technical standards. Proper use of the shop manual minimizes errors‚ enhances safety‚ and prolongs the sled’s lifespan. It is essential for both routine care and troubleshooting‚ making it a vital companion for every Ski-Doo enthusiast.

Pre-Ride Checks and Safety

Ensuring your Ski-Doo is ready for the ride is crucial for safety and performance. Begin with a thorough inspection of fluid levels‚ battery charge‚ and brake functionality. Check the condition of belts‚ tracks‚ and skis for wear or damage. Familiarize yourself with controls and ensure all safety features‚ like the kill switch‚ are functioning properly. Always wear protective gear‚ including a helmet‚ goggles‚ and gloves. Review hand signals and communication protocols to maintain group safety. Adhere to local regulations and trail rules to ensure a safe and enjoyable experience for all riders.

Always inspect fluid levels‚ battery‚ brakes‚ and tracks before riding. Ensure controls function properly and wear protective gear. Check skis and belts for wear or damage.

3.1 Essential Pre-Ride Checks for Safety

Performing essential pre-ride checks ensures a safe and enjoyable experience. Start by inspecting the tracks for wear and damage‚ ensuring proper tension and alignment. Check the skis and suspension for any signs of wear or damage‚ as these components are critical for stability and control. Verify that all fluid levels‚ including oil and coolant‚ are at the recommended levels to prevent engine damage. Additionally‚ test the brakes to ensure they are functioning correctly and inspect the throttle and brake levers for smooth operation. Finally‚ check the battery terminals for corrosion and ensure all electrical connections are secure. These steps help prevent unexpected issues and ensure your Ski-Doo is ready for the ride.

3.2 Familiarizing Yourself with Controls

Familiarizing yourself with your Ski-Doo’s controls is crucial for safe and effective operation. Start by locating the throttle‚ brake lever‚ and kill switch‚ as these are essential for speed control and emergencies. The throttle‚ typically on the right handlebar‚ regulates engine speed‚ while the brake lever on the left controls deceleration. The kill switch‚ often nearby‚ shuts off the engine quickly if needed. Additionally‚ understand the hand and foot controls‚ such as the starter button or pull cord‚ and ensure all components function smoothly. Always consult your manual for model-specific control layouts to ensure proper operation.

3.3 Checking Fluid Levels and Battery

Regularly checking fluid levels and the battery is vital for optimal Ski-Doo performance. Start by inspecting the coolant‚ oil‚ and brake fluid levels‚ ensuring they meet the manufacturer’s specifications. Refer to your manual for guidance on location and required levels. Next‚ examine the battery terminals for corrosion and secure connections. Test the battery voltage and charge it if necessary‚ especially before storage. Proper fluid levels and a well-maintained battery ensure reliable starting and functioning of essential systems. Always follow safety precautions when handling electrical and fluid components to avoid accidents.

Starting and Operating

Starting and operating your Ski-Doo requires attention to detail to ensure safety and performance. Begin with the manual starter by pulling the recoil handle smoothly until resistance is felt‚ then pulling sharply to engage the ignition. For electric start models‚ simply turn the key or press the start button. Always wear protective gear and ensure the area is clear. Familiarize yourself with controls like the throttle‚ brake‚ and kill switch. Adjust your riding position for comfort and balance. Refer to your manual for specific starting procedures and operation guidelines tailored to your model year and features.

Starting and operating your Ski-Doo involves manual or electric start procedures. Ensure protective gear is worn‚ controls are understood‚ and the area is clear for safe operation.

4.1 Manual Starter Procedure

The manual starter‚ located at the engine flywheel‚ is a standard feature on most Ski-Doo models. To start‚ ensure the sled is on a flat surface and the brake is engaged. Pull the starter handle smartly; a firm‚ quick motion ensures proper engagement. If the engine doesn’t start immediately‚ repeat the process. Note that electric start models may differ‚ with an automatic rewind feature. Always refer to your specific model’s shop manual for detailed instructions‚ as procedures may vary slightly between years and designs. Proper starting techniques are crucial for longevity and performance of your Ski-Doo.

4.2 Electric Start Models and Their Operation

Electric start models offer a convenient alternative to manual starting. Locate the ignition switch‚ ensure the sled is in neutral‚ and turn the key to the “start” position. The electric starter motor will engage automatically. If the engine doesn’t start‚ release the key and wait a few seconds before retrying. Some models feature an automatic rewind system‚ simplifying the process. Always refer to your Ski-Doo’s specific shop manual for detailed instructions‚ as procedures may vary by model year and design. Proper operation ensures reliability and extends the life of your snowmobile’s electrical system.

4.3 Troubleshooting Starting Issues

If your Ski-Doo fails to start‚ check the ignition switch and ensure the kill switch is not engaged. For electric start models‚ verify the battery is charged and connections are clean. A dead battery or loose wires can prevent the starter from engaging. For manual starters‚ ensure the recoil system is functioning properly and the engine is not seized. If issues persist‚ consult your Ski-Doo shop manual for specific diagnostic steps. Always test the battery voltage and inspect the starter motor for damage. If problems remain unresolved‚ contact a certified technician to avoid further complications.

Maintenance and Repairs

Regular maintenance is crucial to extend the life of your Ski-Doo. Follow the routine schedule outlined in your shop manual‚ including oil changes‚ belt inspections‚ and suspension lubrication. Winterization involves draining fuel‚ fogging the engine‚ and protecting the exhaust. Address repairs promptly to prevent minor issues from escalating. For complex problems‚ consult a certified technician. Always refer to the official Ski-Doo service manual for detailed procedures and specifications. Proper care ensures optimal performance‚ safety‚ and reliability during your snowmobiling adventures.

Regular maintenance ensures longevity and performance. Follow the routine schedule‚ including oil changes‚ belt checks‚ and winterization. Address repairs promptly to avoid major issues.

5.1 Routine Maintenance Schedule

A well-structured maintenance schedule is crucial for optimal Ski-Doo performance. Regular checks include oil changes‚ filter replacements‚ and belt inspections. Ensure all components are serviced as recommended to prevent wear and tear. Additionally‚ inspect the suspension and brakes for any signs of damage or degradation. Always refer to the specific model’s shop manual for detailed intervals and procedures. Proper maintenance not only enhances reliability but also extends the lifespan of your snowmobile‚ ensuring safe and enjoyable rides throughout the season.

5.2 Winterization Process

Proper winterization ensures your Ski-Doo remains in excellent condition during storage. Start by draining the cooling system and refilling it with a 50/50 antifreeze mix. Fog the engine to prevent corrosion and lubricate all moving parts. Disconnect the battery and store it in a cool‚ dry place. Seal the exhaust and intake to prevent pests from nesting. Use a high-quality‚ breathable cover to protect the sled from dust and moisture. Avoid direct sunlight to prevent exterior fading. Follow these steps to safeguard your Ski-Doo and ensure it’s ready for the next season.

5.3 Common Repairs and When to Seek Help

Common Ski-Doo repairs include addressing track wear‚ suspension issues‚ and electrical faults. Regularly inspect belts and replace them if worn. Engine fogging and carburetor cleaning are essential after storage. For complex problems like engine damage or transmission failure‚ consult a certified technician. If repairs require specialized tools or exceed your expertise‚ seek professional assistance to avoid further damage. Always refer to your shop manual for guidance‚ and ensure repairs align with manufacturer specifications to maintain your sled’s performance and warranty. Timely professional help prevents minor issues from becoming major problems.

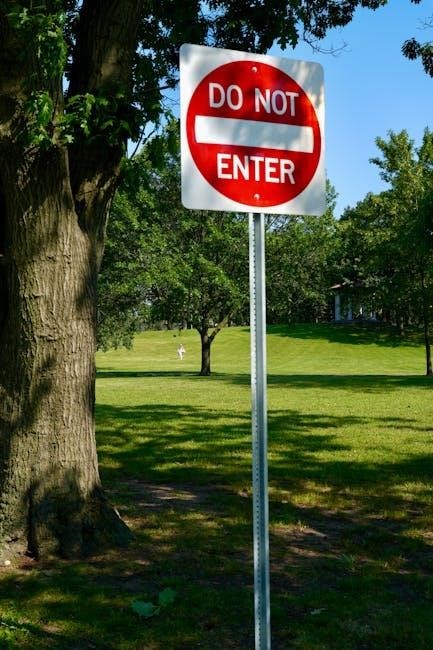

Safety Guidelines

Safety is paramount when operating a Ski-Doo. Always wear approved protective gear‚ including a helmet‚ goggles‚ and gloves. Familiarize yourself with hand signals to communicate effectively with others. Be aware of your surroundings‚ especially in groups‚ to prevent collisions. Check weather and trail conditions before heading out. Carry a first-aid kit and ensure your phone is fully charged. Never ride under the influence of alcohol or drugs. Stay alert to potential hazards like ice‚ obstacles‚ and avalanches. Respect the environment and other riders to ensure a safe and enjoyable experience for everyone.

Always wear protective gear‚ including a helmet and goggles. Use hand signals for clear communication. Avoid riding under the influence and stay alert to hazards like ice and obstacles.

6.1 Basic Hand Signals and Communication

Effective communication is vital for safe group riding. Use hand signals to indicate stopping‚ turning‚ or slowing down. These signals help maintain coordination and awareness among riders. Always ensure clear visibility of signals‚ especially in low-light conditions. Verbal communication should be loud and clear to overcome engine noise. Familiarize yourself with universal hand signals to avoid confusion. Proper communication prevents accidents and ensures a smooth‚ enjoyable ride for everyone involved. Regularly check that all riders understand and are using signals correctly. This promotes safety and harmony within the group.

6.2 Essential Protective Gear

Always wear essential protective gear to minimize injury risk while riding. A helmet is mandatory‚ providing critical head protection. Goggles protect eyes from snow‚ wind‚ and debris. Insulated‚ waterproof gloves enhance grip and dexterity. Durable boots with good traction prevent slipping. A snowmobile suit or jacket and pants offer weather protection and abrasion resistance. Consider a neck roll or scarf for added neck protection. Ensure all gear fits properly and is suitable for winter conditions. Following manufacturer guidelines ensures optimal safety and comfort during your ride.

6.3 Avalanche Safety and Awareness

Avalanche safety is crucial for backcountry snowmobiling. Always assess terrain for potential risks and carry essential tools like a transceiver‚ probe‚ and shovel. Check local avalanche forecasts and avoid unstable slopes. Travel with a group and stay within sight of each other. If caught in an avalanche‚ stay calm and follow survival techniques. Knowing how to respond can save lives. Take certified avalanche safety courses to improve awareness and decision-making skills. Never underestimate the power of snow conditions and always prioritize caution in high-risk areas.

Accessories and Customization

Enhance your Ski-Doo experience with accessories designed to fit your needs. The LinQ attachment system offers quick and easy installation of items like storage bags‚ racks‚ and more. Customize your sled with performance upgrades‚ protective gear‚ and styling options to reflect your personality. BRP provides a wide range of genuine accessories to ensure compatibility and quality. Whether for utility or aesthetics‚ these additions can transform your snowmobile into a tailored machine. Always consult your shop manual for installation guidelines to maintain your Ski-Doo’s optimal performance and warranty.

The LinQ attachment system allows easy customization of your Ski-Doo with accessories like storage solutions and performance upgrades. BRP offers genuine parts for personalized enhancements.

7.1 The LinQ Attachment System

The LinQ system offers a versatile and secure way to attach accessories to your Ski-Doo‚ enhancing functionality and personalization. Designed for quick installation‚ it transforms your snowmobile with minimal effort. Whether adding storage solutions‚ performance upgrades‚ or utility items‚ LinQ ensures compatibility and durability. This system is tailored to fit various Ski-Doo models‚ providing a seamless integration of accessories. Its robust design ensures reliability in all riding conditions‚ allowing you to customize your sled to meet your specific needs effortlessly.

7.2 Customizing Your Ski Doo

Customizing your Ski-Doo enhances performance and personal style. From engine upgrades to aesthetic modifications‚ adjustments can be made to suit riding preferences. Accessories like handlebars‚ skis‚ and exhaust systems improve functionality. The LinQ attachment system simplifies adding storage or utility items. Ensure all modifications comply with manufacturer guidelines to maintain warranty and safety. Consult the shop manual or a certified technician for complex changes. Personalization allows riders to tailor their sled for optimal comfort and performance‚ making each Ski-Doo unique to its owner’s needs and preferences.